APEX SIPS

“For the Love of Building”

Better Materials. Better Process. Better Builds

Forty Years of Building

Twenty Years of making it Better

I started manufacturing Structural Insulated Panels twenty years ago because the building science made sense — and because I was tired of watching good houses lose energy through the same framing problems everybody just shrugs at.

Every Apex SIPs project is engineered and stamped by a licensed PE.

When you call us, you talk to me. That's how this works."

John Pardue-Founder

The problem every builder already knows

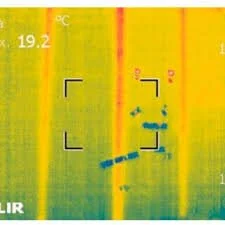

A stick-framed wall is 15 to 25 percent lumber. Every one of those studs is a thermal bridge — a highway for heat and cold to pass right through your insulation like it isn't even there. You stuff fiberglass batts or spray foam between the studs, tape up some house wrap, and hope for the best.

Then you hang a massive HVAC system on the house to compensate for all the energy it's leaking.

That's not Building Science.

That's just how we've always done it.

A building System

Not a Pile of Lumber

A Structural Insulated Panel is simple — two sheets of structural-rated OSB with a rigid foam core bonded between them. Structure and insulation in one piece. No studs every 16 inches. Minimal thermal bridging. No gaps for air to find its way through.

But the panel is just where it starts. Every Apex project is a complete building system — walls, roof, engineered connections, and a sealed envelope designed to work together. Your panels show up to the jobsite pre-cut to your plans and ready to assemble. What used to take a framing crew weeks gets dried in in days.

50% more energy efficient than conventional stick framing — SIPA

55% less framing labor on site — BASF time-motion study

15x more airtight than comparable stick-framed assemblies — Oak Ridge National Laboratory

90 years of development — from the Forest Products Lab in 1935 to mass production today